Short-term plastics—single-use items or those employed for only a short period of time—represent a long-term environmental problem. But in the search for sustainable alternatives, researchers may have just hit the sweet spot.

Plastics are commonly used for short-term products and applications, but they persist in the environment long past their usefulness, causing pollution and damage to ecosystems on a huge scale. Attempts to create bioplastics have resulted in new materials, often from biomass and natural waste products, but many of these still do not completely degrade under natural conditions.

Now, researchers at Boise State University, USA, report on a new class of lightweight materials made from small-molecule sugars rather than polymers. Their work is based on the premise that the solution to plastic use and waste is not new plastics, but in fact a different class of short-lived materials made from renewable resources. Ideally, these materials should offer efficient recycling, rapid degradation into harmless components, and the ability to be produced using existing plastic processing methods.

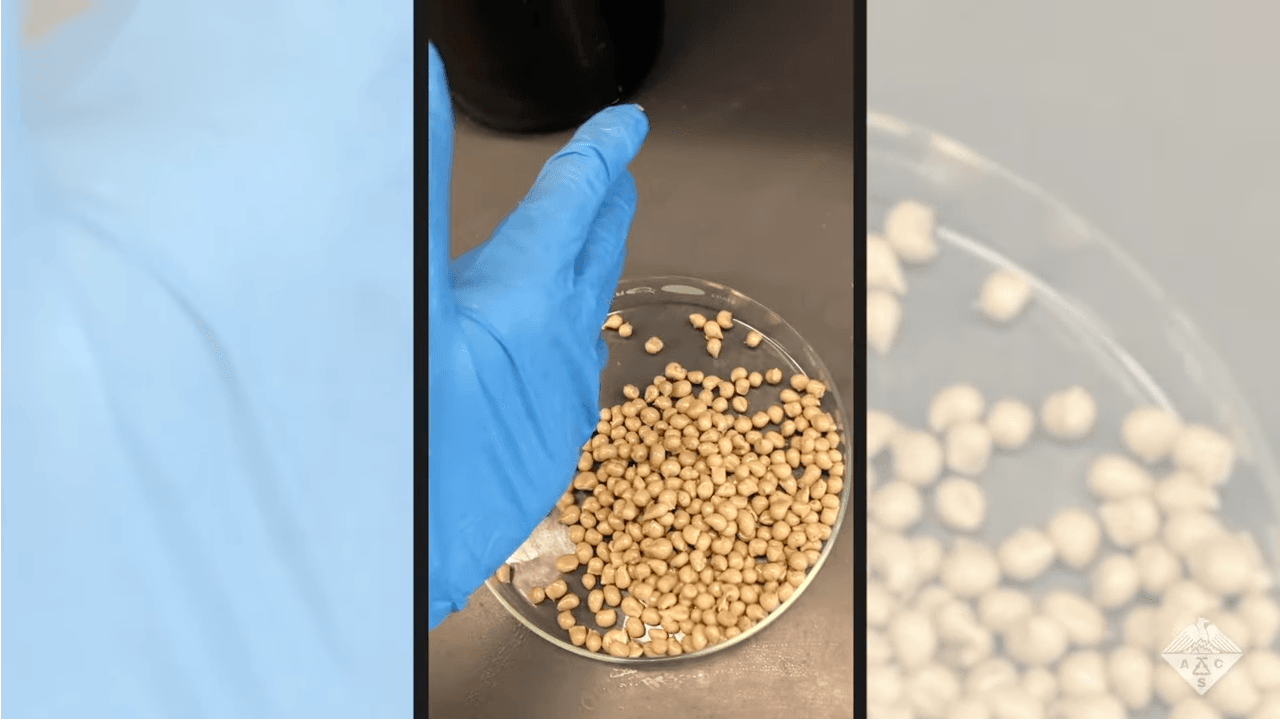

The paper, published in ACS Sustainable Chemistry & Engineering, describes how this biomass-based material can be efficiently injection-molded at low temperatures. Using a matrix of amorphous isomalt and natural additives such as wood flour or sawdust, the team developed several rigid yet lightweight materials with strengths similar to that of ceramic or stone.

Catalytic Techniques for Upcycling Plastic Waste

When tested, the uncoated sample materials were able to withstand exposure to humidity up to 50% at 20°C, and samples coated in a shellac and cellulose acetate displayed water resistance for up to a week when fully submerged. However, when the coating was broken, the materials dissolved in water within minutes, degrading back into isomalt and bio-based additives that could serve as nutrients for soil. And the icing on the cake—the researchers were able to repeatedly break down and recycle the materials into new ones via a closed-loop process without degradation of the isomalt binder or loss of mechanical properties.

The authors note several additional benefits of amorphous isomalt as a promising single-use alternative: it is widely available on a global scale, it is stable to thermal treatments, and it has been used before to form a stable glass. In addition, it has low hygroscopicity—a characteristic which makes it resistant to microbial growth.

These findings could represent a scalable and environmentally friendly replacement for rigid thermoplastics for short-term-use applications. The authors suggest ideal applications may include single-use food service items or seasonal and event décor, since products in these categories need only to withstand storage, transportation, and short-term use.

Watch the video around this research created by the ACS Science Communications team:

Stay Connected

Information for Authors

Explore Related Research from ACS Journals

Sugar-Core Synthesized Multibranched Polylactic Acid and Its Diacrylate Blends as a UV LED-Curable Coating with Enhanced Toughness and Performance

Thananchai Piroonpan, Kasidit Booncharoen, and Wanvimol Pasanphan

DOI: 10.1021/acssuschemeng.2c02958

Economic and Environmental Benefits of Modular Microwave-Assisted Polyethylene Terephthalate Depolymerization

Yuqing Luo, Esun Selvam, Dionisios G. Vlachos, and Marianthi Ierapetritou

DOI: 10.1021/acssuschemeng.2c07203

Technical, Economic, and Environmental Comparison of Closed-Loop Recycling Technologies for Common Plastics

Taylor Uekert, Avantika Singh, Jason S. DesVeaux, Tapajyoti Ghosh, Arpit Bhatt, Geetanjali Yadav, Shaik Afzal, Julien Walzberg, Katrina M. Knauer, Scott R. Nicholson, Gregg T. Beckham, and Alberta C. Carpenter

DOI: 10.1021/acssuschemeng.2c05497