Clean, safe water is a limited resource, but there are trillions of liters of water vapor in the air. Could extracting this be the key to avoiding some of our looming resource issues?

According to the National Geographic, more than 99% of Earth's water is unusable by humans and many other living things.1 This figure is startling, and with our growing global population water shortages are going to become an inevitable reality unless we can think our way out of trouble. If not, it is estimated that 40% of global annual water demand will not be met by 2030.2 Places in the United States are already fighting over the dwindling waters of the Colorado River,3 and when disputes cross national borders, the stakes are likely to be raised. Yet there are trillions of liters of water vapor in the air, and extracting this could ease our reliance on traditional bodies of fresh water.

To explore this, a team in Massachusetts has designed a compact multicyclic high-performance atmospheric water harvester for arid environments.4 Reporting their findings in ACS Energy Letters, the authors argue that the emerging science of sorption-based atmospheric water harvesting (SAWH) is a promising solution for water scarcity—especially in arid and non-coastal regions with low humidity, where traditional approaches such as fog harvesting and dewing do not work. An interesting 2021 review in ACS Nano looked at state-of-the-art technologies for water capture strategies, with a focus on solar power,5 and another in 2022 focused specifically on atmospheric water harvesting.6 In this process, atmospheric water is captured using hygroscopic materials. Traditionally this might have been halide salts and their composites, but now includes emerging materials, such as those based on metal–organic frameworks or other sorption materials. The harvested atmospheric water is then released by a solar-driven thermal process and collected via condensation.

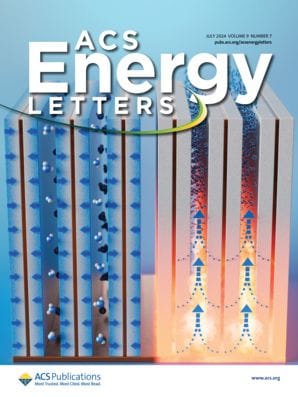

Yet despite advances in materials development, most early devices in the field have not been able to drive sufficient water production. In the new study, the team focused on an adsorption bed design in order to achieve higher water production. Initial modeling and experimental validation suggested an optimized design could be achieved with a fin-array adsorption bed, rather than traditional flat coatings. The air gap between the fins is a key design parameter to maximize water adsorption, and minimize mass transfer resistance. This aligns with previous work which has looked at porous materials for water adsorption devices, where water condenses in the gaps or pores.7 The resulting harvesting device is driven by high-density waste heat, therefore enabling fast cycling kinetics and maximizing daily water production.

Design of a Compact Multicyclic High-Performance Atmospheric Water Harvester for Arid Environments

DOI: 10.1021/acsenergylett.4c01061

Water vapor in the Earth’s atmosphere accounts for around 10% of freshwater sources, or 50,000 cubic kilometers.8 But despite the material advances, challenges remain in the field. From a technological point of view, one of the most significant needs is to balance the requirement of moisture concentration and water release. There are also wider questions about how mass extraction of water vapor could affect the Earth’s already destabilized natural cycles. At present, there are no easy answers, but hopes are pinned on the science to chart us a clean and sustainable path.

Stay Connected with ACS Energy Letters

References

- https://education.nationalgeographic.org/resource/earths-fresh-water/

- Mekonnen, M. M. and Hoekstra, A. Y. Four billion people facing severe water scarcity. Sci. Adv. 2016, 2, e1500323

- https://today.usc.edu/the-water-wars-of-the-future-are-here-today/

- Li, X. et al. Design of a Compact Multicyclic High-Performance Atmospheric Water Harvester for Arid Environments. ACS Energy Lett. 2024, 9, 3391–3399.

- Li, Z. et al. Solar-Powered Sustainable Water Production: State-of-the-Art Technologies for Sunlight–Energy–Water Nexus. ACS Nano 2021, 15, 8, 12535–12566.

- Liu, X. et al. Water Harvesting from Air: Current Passive Approaches and Outlook. ACS Materials Lett. 2022, 4, 5, 1003–1024.

- Furukawa, H. et al. Water Adsorption in Porous Metal–Organic Frameworks and Related Materials. J. Am. Chem. Soc. 2014, 136, 11, 4369–4381.

- Zhou, X. et al. Atmospheric Water Harvesting: A Review of Material and Structural Designs. ACS Materials Lett. 2020, 2, 7, 671–684.