Researchers have developed a three-stage polymer process that transforms soft, light-sensitive holographic films into rigid, glassy materials without sacrificing optical precision.

For decades, one major obstacle has kept holographic photopolymers from graduating from the lab and into real-world devices: they've been too soft. To record a hologram, scientists need a material that's both rubbery and mobile, allowing light-sensitive molecules to move and form intricate patterns. But those same properties make the resulting hologram unstable. When heated or handled, the flexible film can warp, distort, or even lose its pattern altogether.

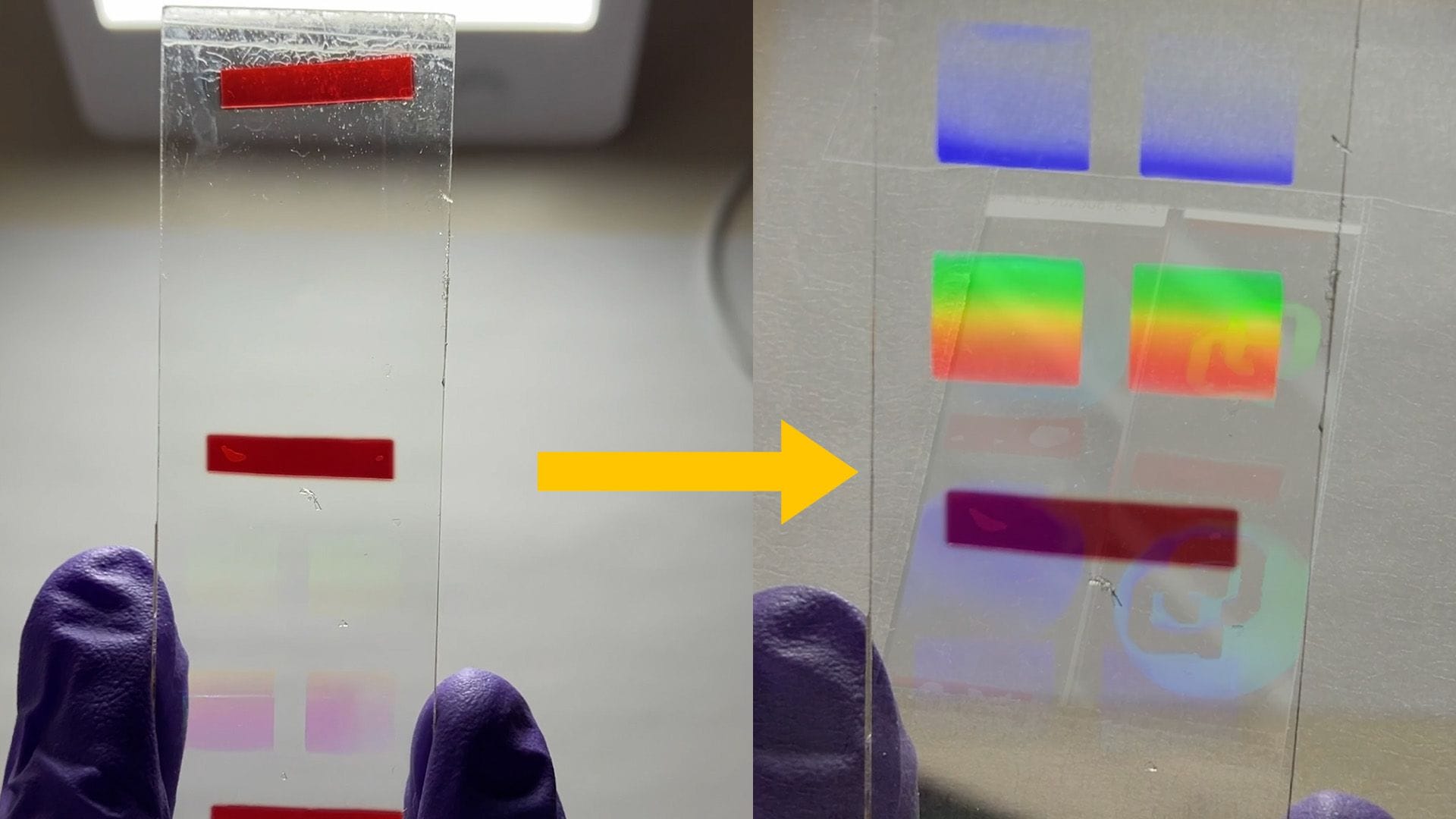

This tension between optical perfection and mechanical stability has long frustrated scientists working toward next-gen technologies such as augmented reality displays, sensors, and optical security features. But a team at the University of Colorado Boulder recently reported on a breakthrough: a three-stage "multinetwork" photopolymer that can shift from soft to rigid without losing its holographic structure.

A recent Headline Science short captures this research in motion:

A polymer that evolves in stages

Traditional systems use two stages—one for patterning, another for curing—but this design adds a crucial third stage:

- Stage 1: A flexible polyurethane matrix gives the system the mobility it needs to record a hologram.

- Stage 2: During exposure to patterned violet light, acrylate monomers polymerize at the bright interference fringes, forming the light-sensitive grating that defines the hologram.

- Stage 3: A final epoxide reaction, activated by heat after writing, is what truly transforms the material. It raises the glass transition temperature (Tg) from –22 °C to 101 °C, “locking” the delicate light pattern into a solid, glassy network.

This final step allows the hologram to be written under ideal conditions and then permanently fixed in a stable form—something researchers have been chasing for more than 30 years.

The results, published in ACS Applied Materials & Interfaces, speak for themselves. Even after thermal curing, the team’s holographic films recorded an initial diffraction efficiency of 89% and a refractive index contrast of 0.0057, showing that the microscopic light-diffracting structure survived intact. Dynamic mechanical analysis revealed the shift in material behavior from a soft, easily deformable polymer to a rigid, glasslike solid. Atomic force microscopy confirmed that the fine holographic fringes remained consistent through every stage of curing, even as the material’s internal structure tightened and cross-linked.

Bending the rules of holography

Because this multistage system starts soft and ends strong, it also enables something rarely possible in holography: reshaping after recording.

To demonstrate, the researchers laminated a flat, holographic film onto a curved cylindrical lens. After the final thermal cure, the hologram retained both its structure and its ability to diffract light precisely, even on the new curved surface. The result is a monolithic, dimensionally stable optical element that could inspire future transparent displays, light-guiding devices, or adaptive optical sensors.

This work shows that holographic materials no longer need to trade optical quality for strength opening new possibilities for durable, customizable optical components in next-generation photonic devices.

Watch more Headline Science on YouTube!

The video above is brought to you by the ACS Science Communications team. To watch more exciting videos and shorts covering some of the latest research in ACS journals, visit the Headline Science page on YouTube.

Video credits:

Written and produced by Anne Hylden

Edited and animated by Janali Thompson

Narrated by Chris McCarthy

Series produced by Vangie Koonce, Anne Hylden, Andrew Sobey, and Jefferson Beck

Executive produced by Matthew Radcliff

Explore related articles from ACS journals

Holographic Photopolymers via Two-Stage Orthogonal Thiol-Click Chemistries Leveraging Kinetic Selectivity

John F. Rynk, Yunfeng Hu, Maciej Podgórski, Benjamin R. Nelson, Andrew N. Sias, Robert R. McLeod, and Christopher N. Bowman*

DOI: 10.1021/acsapm.5c00044

Holographic Photopolymer Gratings: A Step toward Wound Temperature Sensing

Pamela Stoeva, Dervil Cody, Suzanne Martin, and Izabela Naydenova*

DOI: 10.1021/acsaom.4c00504

Initiation-Confined Holographic Photopolymerization under Visible Light

Jie Chen, Wei Wei, Haiyan Peng*, Mingli Ni, Hongxi Guo, Dengfu Lu, Yonggui Liao, Xingping Zhou, Zhong’an Li, and Xiaolin Xie*

DOI: 10.1021/jacs.5c06053

Reducing Haze of Holographic Gratings Recorded in a Two-Stage Photopolymer

Yunfeng Hu, Marianela Trujillo-Lemon, Andrew N. Sias, Adam L. Dobson, Maciej Podgórski, Jasmine Singh, Sudheendran Mavila, Robert R. McLeod, and Christopher N. Bowman*

DOI: 10.1021/acs.macromol.4c02398

Thiol–Ene Photopolymerization Enhances Liquid Crystal Ordering and Structural Regularity in Holographic Polymer Nanocomposites: A Coupled DPD-FDTD Simulation

Wei Wei, Song Li*, Xingping Zhou, Haiyan Peng*, and Xiaolin Xie

DOI: 10.1021/acs.macromol.4c02287