A new biomimetic material inspired by the silent flight of owls could lead to a quieter world—from highways to industrial sites and beyond.

Owls are famous for how little sound they make while flying. Their wings are designed to muffle the rush of air, allowing them to swoop silently toward prey. That same natural design has now inspired a team of materials scientists to create an ultralight aerogel capable of reducing a wide range of noise frequencies without the bulky weight or limited performance of conventional soundproofing materials.

The problem with—and a solution to—traditional noise barriers

Noise pollution can have a serious impact on human health. It also impacts the health and well-being of wildlife: for example, it can cause change in physiological responses in caterpillars, and decrease the number of chicks a bluebird will raise. Sound is often crucial for both land and aquatic organisms to navigate, feed, attract mates, and avoid predators. Where eliminating noise or controlling it at the source is not possible, using sound-absorbing materials is a simple and quick approach that has been widely adopted.

But most noise-reduction materials struggle with trade-offs. Dense foams and fibrous panels can absorb high-frequency sound but perform poorly at lower frequencies like those produced by engines or heavy machinery. Multilayered designs can improve performance, but at the cost of weight, rigidity, and expense—limitations that make them impractical for many real-world applications.

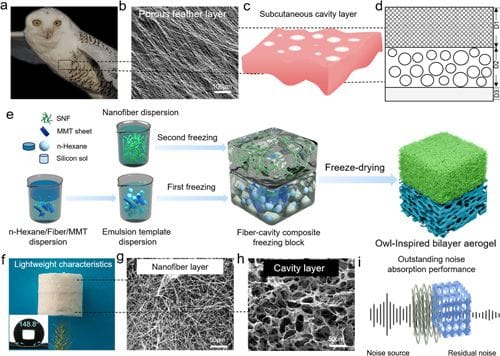

To break that cycle, researchers turned to nature’s quietest flyer: the owl. Owl feathers combine a soft, porous layer and a flexible cavity structure that work together to dampen both low- and high-frequency sound. Mimicking that unique “skin-feather coupling” became the inspiration for a new kind of lightweight, flexible, and acoustically versatile aerogel.

Building the owl-inspired aerogel

The researchers used an advanced electrospinning method to create flexible silica nanofibers, the foundation of their design. These ultrathin fibers were arranged into a delicate membrane using a sol–gel process, then bonded with layers of montmorillonite nanosheets—a mineral that adds strength and thermal stability.

Through a combination of emulsion templating, freeze-drying, and structural reconstruction, the team crafted what they call owl-inspired structured nanofiber aerogels (OSNAs). Like the owl wing they emulate, the aerogel features two distinct yet complementary layers:

- A fluffy fiber layer that dissipates high-frequency sound waves.

- A cavity layer that captures and scatters lower-frequency vibrations.

The result, reported in ACS Applied Materials & Interfaces, is a biomimetic structure that channels sound energy through multiple scales of pores and fibers, breaking up noise instead of reflecting it.

The results: silence by design

When tested, the OSNAs displayed remarkable acoustic performance across a broad frequency range (63–6300 Hz). The material achieved an impressive noise reduction coefficient (NRC) of 0.58, outperforming many commercial acoustic absorbers. When a small air cavity was introduced behind the material, that value climbed to 0.69, further extending its sound-dampening capabilities.

In practical terms, the aerogel reduced automobile engine noise by nearly 9 decibels, an audible drop even to the untrained ear. Despite its softness and low density, the material remained durable—retaining shape after 100 compression cycles at 60% strain with only 5% deformation.

Applications for a quieter future

This owl-inspired innovation could enable a new frontier in sustainable noise control. The lightweight, flexible aerogel could one day be integrated into vehicle panels, building materials, or industrial enclosures, reducing both environmental noise and energy consumption compared to traditional materials.

Explore More ACS Journal Articles on Noise Reduction Materials and Technologies

Polyacrylonitrile/Polyurethane Nanofiber/Boron Nitride Nanosheet Sponges for Noise Reduction

Jiaxin Zhao, Sai Wang*, Zixin Dai, Roman A. Surmenev, Shichao Zhang, Jianyong Yu, and Bin Ding*

DOI: 10.1021/acsanm.5c01325

Construction of an Asymmetric Structure to Enhance the Sound Absorption and Mechanical Properties of PUF/Polypropylene Honeycomb Composites

Yan Sun, Junhe Zhang, Gaohui Sun*, Xiaohe Ren*, Xin Fu, Guocheng Zhou, Jun Wang, and Shihui Han*

DOI: 10.1021/acsapm.5c00859

Ambiently Dried Aerogel-Foam Composites with Gradient Pore Structure for Enhanced Sound Absorption

Caide Fan, Jin Yang, Meili Rui, Jianming Yang, Tengyan Shi, Jun Shen, Bin Zhou, Chen Liu*, Jie Zhu*, and Ai Du*

DOI: 10.1021/acsami.4c23072

Lightweight Porous Aerogels Comprising Nanofibrillated Cellulose and MXene Nanosheets for Simultaneous Microwave and Sound Absorption Applications

Meng Zhu, Weiyun Chen, Yuting Lei, Zhichao Zhang, Penghao Gao, Yongjian Xu*, and Hailong Xu*

DOI: 10.1021/acsanm.4c07200

Highly Compressible Micro/Nanofibrous Sponges with Thin-Walled Cavity Structures Enable Low-Frequency Noise Reduction

Meng Geng, Zikang Ding, Yaqian Jian, Zixin Dai, Fei Wang*, Jianyong Yu, Shichao Zhang*, and Bin Ding

DOI: 10.1021/acs.nanolett.4c05906

Gradient Pore-Structured Polymeric Fibrous Aerogels for Effective Low-Frequency Noise Absorption

Sruthi Suresh, Rajan B. Amal Raj, Ajna Parol M, and E. Bhoje Gowd*

DOI: 10.1021/acsapm.4c01904

Novel Wood-Based Functional Material with Vibration and Noise Reduction

Liyuan Zhang, Conglin Dong*, Chengqing Yuan*, and Xiuqin Bai

DOI: 10.1021/acsami.3c06508