Researchers reveal a safer, scalable way to align boron nitride nanotubes using liquid crystal dispersions, opening new opportunities for high-performance materials.

Boron Nitride Nanotubes (BNNTs) are tiny, lightweight structures made of rolled hexagonal sheets of boron and nitrogen atoms. They are similar in structure to their carbon nanotube siblings, but they combine mechanical strength, thermal stability, and chemical resistance in a way that’s rare for nanomaterials. While BNNTs are still emerging in commercial applications, they have demonstrated great potential for use in advanced technologies such as aerospace equipment, thermal management, and drug delivery systems.

So how do you take the extraordinary properties of individual BNNTs and translate them into large, usable materials? The key lies in achieving precise control over how these nanotubes line up and organize themselves together. Perfect BNNT alignment can unlock their full strength and efficiency, but traditional methods to achieve this have proven messy, hazardous, or impractical.

A safer path to alignment

A cost-effective and scalable approach to BNNT alignment involves processing dispersions in a liquid crystalline phase. One of the most effective solvents for dispersing BNNTs was chlorosulfonic acid, a highly corrosive chemical that is difficult to handle outside of specialized labs. To investigate BNNT alignment using a safer alternative, a team of researchers have developed an approach using aqueous dispersions stabilized with sodium deoxycholate (SDC), a common surfactant.

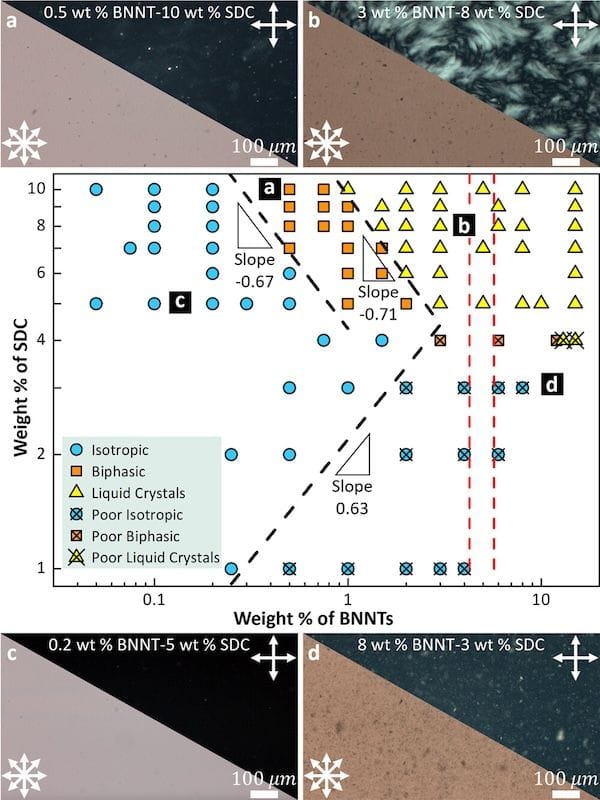

By carefully controlling BNNT–SDC concentration ratios, the team were able to coax the nanotubes into forming liquid crystalline phrases—states where the nanotubes self-organize into ordered domains, much like the molecules inside LCD screens. Using techniques such as polarized light microscopy, scanning electron microscopy, and cryogenic electron microscopy, they directly observed how BNNTs transitioned from a disordered (isotropic) state into partially aligned (biphasic), and finally to fully aligned nematic phases.

While the science is precise, the visuals are otherworldly. A recent Headline Science video shows the research in action, revealing how subtle shifts in concentrations drive the mesmerizing emergence of liquid crystalline order—a glimpse of nanoscale self-assembly with enormous potential.

Building a roadmap

One of the major outcomes of this work, published in Langmuir, is the first phase diagram for BNNT–surfactant systems, demonstrating exactly how different ratios of BNNTs and surfactant affect whether the material remains disordered or becomes highly aligned. This roadmap can be a powerful tool for other researchers, offering a guide to reliably produce dispersions with the desired properties.

Toward high-performance materials

This study marks a step forward in harnessing BNNTs for high-performance applications. With a safer, water-based method for organizing these nanotubes, industries could one day produce materials that are stronger, lighter, and more heat-resistant than current options—advancing fields such as aerospace engineering, energy storage, and next-gen electronics.

Watch more Headline Science on YouTube!

The video above is brought to you by the ACS Science Communications team. To watch more exciting videos and shorts covering some of the latest research in ACS journals, visit the Headline Science page on YouTube.

Video credits:

Written by Kerri Jansen

Editing and animations by Vangie Koonce

Narrated by Andrew Sobey

Series produced by Vangie Koonce, Anne Hylden, Andrew Sobey, and Jefferson Beck

Executive produced by Matthew Radcliff

Explore related articles from ACS journals

Aligned Boron Nitride Nanotube Thin Films and Their Cocomposites with Single-Wall Carbon Nanotubes through Slow Vacuum Filtration

Pavel Shapturenka, Tehseen Adel, Frank M. Abel, Angela R. Hight Walker, and Jeffrey A. Fagan*

DOI: 10.1021/acsnanoscienceau.5c00022

Acid-Free Liquid Crystalline Single-Walled Carbon Nanotube Polyelectrolytes for Interconnected Fibers, Yarns, and Electronic Textiles

Sung-Jun Kim, Subin Kim, Keunil Park, Hyelim Kim, Daeyoung Lim, Adam J. Clancy, Milo S. P. Shaffer*, and Won Jun Lee*

DOI: 10.1021/acsnano.5c06382

Highly Thermally Conductive Super-Aligned Boron Nitride Nanotube Films for Flexible Electronics Thermal Management

Yue Yue, Xiaoran Yang, Kai Yang, Kangyong Li, Zexin Liu, Fanfan Wang, Rong Zhang, Jian Huang, Zhiqiang Wang, Lifu Zhang*, and Guoqing Xin*

DOI: 10.1021/acsami.4c05971

Dimension Engineering of Boron Nitride Nanostructures through Catalytic Flash Joule Heating

Jinhang Chen, Yi Cheng*, Phelecia Scotland, Jaeho Shin, Lorenzo Castelli, John Tianci Li, Weiyin Chen, Kevin M. Wyss, Qiming Liu, Obinna E. Onah, Geoff Wehmeyer, Yufeng Zhao*, and James M. Tour*

DOI: 10.1021/acsnano.5c03593

Activated Diffusion of 1D J-Aggregates in Boron Nitride Nanotubes by Curvature Patterning

Jean-Baptiste Marceau, Juliette Le Balle, Duc-Minh Ta, Alberto Aguilar, Annick Loiseau, Richard Martel, Pierre Bon, Raphael Voituriez, Gaëlle Recher, and Etienne Gaufrès*

DOI: 10.1021/acsnano.4c16853

Dispersible Amine-Functionalized Boron Nitride Nanotubes for Applications in Extreme Environments Encountered in the Aerospace and Defense Industry

Unseok Jung, Minhyeok Lee, Jihyeon Lim, Se Youn Moon, Se Gyu Jang, Jonghwan Suhr*, and Hunsu Lee*

DOI: 10.1021/acsanm.5c01454

Confined Growth of Boron Nitride Nanotubes Enabled by Varying Mg-to-Al Ratios in a MgAl2O4 Catalyst

Wentao Zheng, Zhengyang Zhou, Kai Zhang*, Ying Wang, Qian He, Nanyang Wang, Liyun Wu, and Yagang Yao*

DOI: 10.1021/acs.jpcc.5c01085