Imagine a world where plastic waste becomes the raw material for creating value-added products. One new study dives into the fascinating science of bacterial bio-upcyclers turning the tide on pollution, one PET polymer at a time.

Plastic continues to be an ecological problem. In particular, a common thermoplastic material found in many consumer goods is polyethylene terephthalate (PET). Every year, over 82 million tons are used in single-use drinks bottles, packaging, clothing, and carpets.1 Both chemical and biological approaches to PET depolymerization and recycling have been investigated, but in the United States only 28.6% was reported recycled in 2021.2 A third option could be bio-upcycling to convert this ubiquitous plastic waste into high-value molecules that would otherwise be manufactured new from fossil resources.

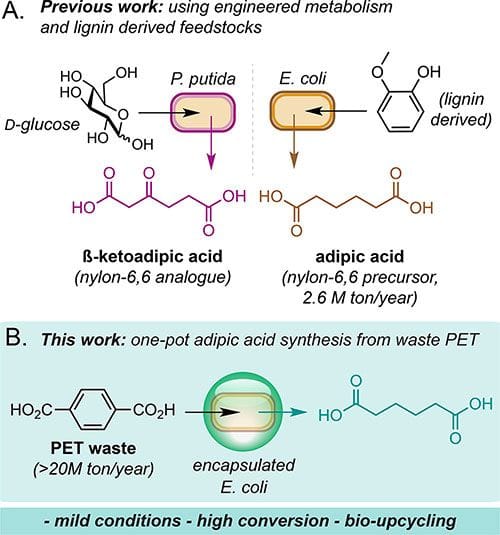

This is the approach being tested by a team of researchers in the United Kingdom. The work, published in ACS Central Science, shows how microorganisms can be genetically engineered to transform waste feedstock into value-added small molecules.3

The team have had previous success with creating adipic acid from guaiacol, a lignin-derived feedstock, using Escherichia coli.4 But this is the first report of a one-pot bio-upcycling method that puts E.coli to work turning PET waste into adipic acid. This molecule is significant because it is a precursor for nylon production, as well as for chemicals in the materials, pharmaceuticals, fragrances, and cosmetics industries. Current adipic acid needs are 2.6 M ton/year, a figure currently met by benzene derived from petrochemicals. Being able to produce it from PET that would otherwise end up in landfill is a significant advance, both in reducing extraction of fossil fuels, and in reducing emissions of greenhouse gases associated with processing.3

Overall, the team needed to gift the E.coli plasmid with eight new genes to allow it to produce adipic acid from PET. These represent a range of enzymes for a de novo biosynthesis pathway. The engineered cells were then immobilized in alginate hydrogels, where the reaction produced adipic acid in 79% conversion (115 mg/L) in 24 hours. Calcified alginate hydrogels have been used before to increase enzyme stability in vitro and improve downstream purification of whole-cell biotransformations, but their use for heterologous enzymes in de novo pathways in E.coli is rare. The authors note they intend to look at cofactor recycling, engineering, scale-up, and extension of this pathway to encompass the microbial synthesis of other industrially significant chemical targets.

E.coli and another gram-negative bacteria called Gluconobacter oxydans have also been used to turn PET into pyrogallol, catechol, and various acids including gallic, muconic, vanillic, and glycolic.5 This range of upcycled chemicals can then be used in manufacturing pharmaceuticals, cosmetics, sanitizers, animal feeds, and bioplastic monomers. Previous work to employ microorganisms in novel recycling technologies has also seen fungus put to work turning polystyrene into carboxylic diacids, and onwards into benzoic acid, ergothioneine, pleuromutilin, and mutilin.6 Much like PET, polystyrene is one of the most commonly used plastics, but also one of the hardest to recycle—with rates of just 0.9% in the United States. Fungi are ideal candidates for plastic upgrading as they grow quickly, have robust biosynthetic capabilities, genetic tractability, inexpensive cultivation requirements, and high fermentation titers.

Developing new sustainable bio-based methods to valorize waste carbon into industrial small molecules is an elegant approach to creating a circular chemicals economy. Especially when considering that chemical recycling of PET has high energy costs, recycling economics can be improved through upcycling to monomers with higher in value than the original PET.

References

- Researchers Engineer Microorganisms To Tackle PET Plastic Pollution. National Renewable Energy Laboratory, 2021.

- US PET recycling rate posts modest increase in 2021. Recycling Today, 2022.

- Valenzuela-Ortega, M. et al. Microbial Upcycling of Waste PET to Adipic Acid. ACS Cent. Sci. 2023, 9, 11, 2057–2063.

- Suitor. J. T., et al. One-Pot Synthesis of Adipic Acid from Guaiacol in Escherichia coli. ACS Synth. Biol. 2020, 9, 9, 2472–2476.

- Kim, H. T., et al. Biological Valorization of Poly(ethylene terephthalate) Monomers for Upcycling Waste PET. ACS Sustainable Chem. Eng. 2019, 7, 24, 19396–19406.

- Rabot, C., et al. Polystyrene Upcycling into Fungal Natural Products and a Biocontrol Agent. J. Am. Chem. Soc. 2023, 145, 9, 5222–5230.