Globally, billions of liters of beer are consumed each year, making it the world’s most popular alcoholic drink. But the science doesn’t end when the brew is finished—how does package type affect flavor and freshness? And is there a clear winner between bottles vs. cans?

Beer is an alcoholic beverage produced by fermenting grain with yeast, often with the addition of hops for flavor. This encompasses a wide range of subtypes, primarily down the lager/ale divide, and from there into wheat beers, fruit beers, bitters, stouts, porters…you get the idea. Each branch in the beer family is characterized by key ingredients as well as fermentation time and temperature, which all have an impact on flavor, texture, and mouthfeel—but how much does packaging influence a beer’s flavor and stability?

Brewers typically use either aluminum cans or glass bottles to package beer. In recent years, there has been a notable shift from bottles to cans, attributed to small canning lines becoming more accessible for craft brewers, changes in consumer activity, and supply chain challenges during the COVID-19 pandemic.

Until recently, a comparison of how glass and aluminum impact beer stability has not been widely explored, and much of the research on beer aging has been performed with lagers—but a team working in Colorado, a state with the fourth most breweries per capita in the U.S., wanted to expand the research to ales. Their work, published in ACS Food Science & Technology, describes a non-targeted metabolomics approach to characterize changes in the metabolite profile of two different ales packaged in either cans or bottles.

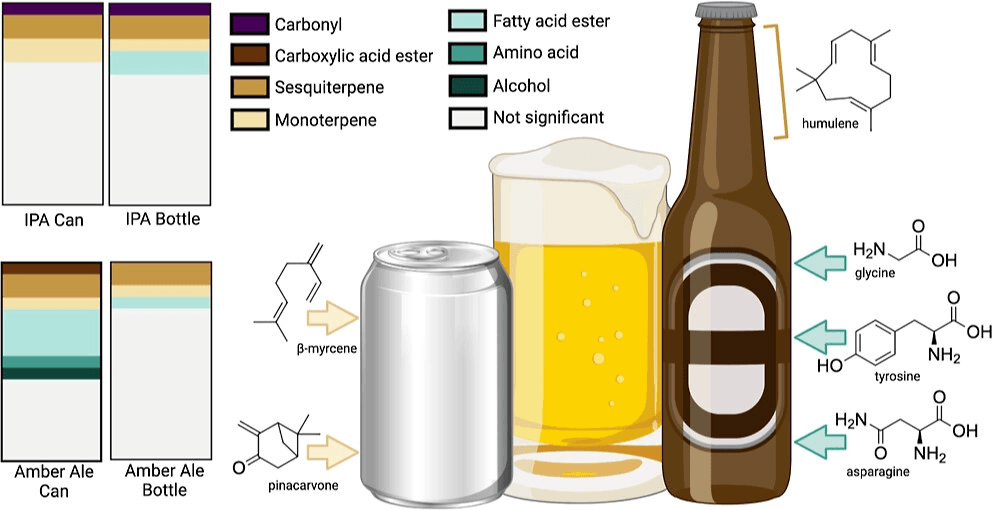

Over a six-month period, the team observed samples of amber ale and India pale ale (IPA) provided by New Belgium Brewing Company in Fort Collins, Colorado. Amber ale is a slow-fermented, medium-bodied beer, whereas IPA is typically lighter in color and packed with hops. After chilling brown glass bottles and aluminum cans of each style for one month, the authors observed both beers at room temperature over the next five months, opening new containers every two weeks and analyzing the respective metabolite profiles.

The results showed a significant correlation in metabolite concentration by package type over all time points for the amber ale (bottles kept it much fresher). The metabolite concentration in the IPA remained relatively unaffected by package material, potentially due to the polyphenols in the hops helping to prevent oxidation and retain amino acids.

However, the researchers observed “flavor scalping” of certain hop terpenes, which occurs when metabolites move from a food or beverage into the packaging materials (such as the polymer linings of cans and bottle caps). Hop terpenes with lower water solubility, such as humulene, are more prone to flavor scalping and getting left behind in the packaging instead of making the journey to your bitter taste receptors. Since hops are one of the key flavor components of beer, their migration patterns are important—and the authors note that significant changes during storage could lead to a beer’s flavor profile and character no longer being “true to brand.”

The absorption of hop volatiles by cap liner polymers and can coatings has previously been investigated, with results published several years ago in the Journal of Agricultural and Food Chemistry. In this work, can coatings were found to absorb hop volatiles in a similar pattern to standard crown bottle caps, but to a lesser extent.

Beer is the most widely consumed alcoholic beverage around the world, and it has been part of human culture for thousands of years. Advances in packaging technology based on this new research might change things in the future, but in the meantime, be sure to store your beer in a cool, dry, and dark place. Cheers to keeping things fresh!

Stay Connected

Explore Related Research from ACS Journals

Yeast Metabolites of Glycated Amino Acids in Beer

Michael Hellwig, Falco Beer, Sophia Witte, and Thomas Henle

DOI: 10.1021/acs.jafc.8b01329

Impact of Beer and Nonalcoholic Beer Consumption on the Gut Microbiota: A Randomized, Double-Blind, Controlled Trial

Cláudia Marques, Liliana Dinis, Inês Barreiros Mota, Juliana Morais, Shámila Ismael, José B. Pereira-Leal, Joana Cardoso, Pedro Ribeiro, Helena Beato, Mafalda Resende, Christophe Espírito Santo, Ana Paula Cortez, André Rosário, Diogo Pestana, Diana Teixeira, Ana Faria, and Conceição Calhau

DOI: 10.1021/acs.jafc.2c00587

Use of Chemical Indicators of Beer Aging for Ex-post Checking of Storage Conditions and Prediction of the Sensory Stability of Beer

Pavel Čejka, Jiří Čulík, Tomáš Horák, Marie Jurková, and Jana Olšovská

DOI: 10.1021/jf403361h

References

- Global Beer Industry – Statistics & Facts. Statista.com.

- Fromuth, K. et al. Characterizing the Impact of Package Type on Beer Stability. ACS Food Sci. Technol. 2023, 3, 4, 616–625.

- Wietstock, P. C. et al. Characterization of the Migration of Hop Volatiles into Different Crown Cork Liner Polymers and Can Coatings. J. Agric. Food Chem. 2016, 64, 13, 2737–2745.

- Watson, B. Craft Beer Packaging Trends Recap, 2020. Brewers Association.