Many consumer products need to be kept cool, but it is not possible for the end user to know whether a temperature threshold has been exceeded. Now, researchers are looking at materials that can give a simple visual cue.

Many foods and medicines need to be refrigerated to prevent them degrading. But while there are protocols for cold-chain transport and storage, it is not possible for the end user to know whether a particular product has exceeded a temperature threshold which could affect its properties, including quality and safety. Electronic sensors can be used, but this is costly and wasteful. Other options include dyes, colloidal photonic crystals, inverse opals, and cholesteric liquid crystals, but these can fade, may have thermo-responsive reversibility once temperature is regained, or they may be too limited in the temperatures they can track— typically working only at higher ranges, which is no good for products such as vaccines and other protein-based medicines that must be kept at very specific cold or sub-zero temperatures.

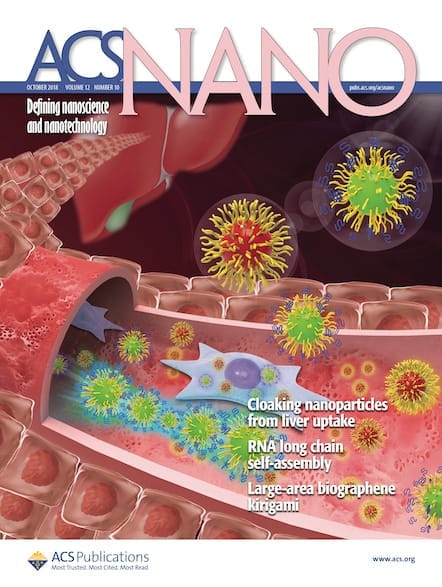

New research published in ACS Nano showcases a structural color-changing material with tunable melting that can be used to track a wide range of temperatures from −70 to +37°C, offering novel benefits over conventional melting dye-diffusion-activated strategies. Structural coloration is a fascinating natural phenomenon in which color is produced by the diffraction of light from microstructures, and structural colors have gained recent attention due to their tunable and eco-friendly properties.

These self-destructive structural color liquids (SCLs) are made from a combination of nontoxic polyethylene glycol or ethylene glycol aqueous solution and a brilliant liquid colloidal photonic crystal. The glycols act as a trigger, since they have high sensitivity to specific temperatures, while the crystals function as an indicator.

Thanks to both their fluidic nature and structural color, the SCLs enable thermal-triggered color changes that can indicate a product’s time–temperature history. The SCL is green when stable, but upon meeting or exceeding the set temperature threshold, the triggering agent flows to the indicator, causing a time-related and irreversible color change by disturbing the periodic structures of colloidal crystal arrays at the interface—turning blue within 5 minutes and decaying to colorless in 120 minutes at the threshold, and even faster at higher temperatures. Theoretically, the time and temperature thresholds can be customized to meet requirements of specific products. The authors suggest these new SCLs can be packaged into labels or QR codes that act as flexible time–temperature indicators and can be assessed via naked-eye inspection or mobile phone scanning.

The collective arrangement of substructures is a simple and cost-effective approach for structural coloration represented by colloidal self-assembly – and could especially be so when combined with 3D printing techniques. Another paper in ACS Nano demonstrates direct 3D writing of nanowire gratings using a femtoliter meniscus of polymer ink.

Metasurfaces have also been studied and may offer advantages such as high resolution and stability under high humidity or high temperatures. A piece published in Nano Letters describes a polarization-switchable dielectric metasurface with full color that can be switched on/off by controlling the polarization of incident light. The authors report that this simple method could one day be used to achieve high-efficiency and polarization-sensitive metasurfaces applicable for color printing and encryption.